The Westlake production sites are IATF 16949:2016-certified

Every Westlake clutch component is individually inspected and tested against set performance specifications before leaving the factory. Tests include fitment, operational capability, wear simulation, stress and fatigue testing using the latest sophisticated testing and inspection facilities. As part of our “Life Test”, clutch kits and component parts are tested using over 500,000 actuations. This ensures that all Westlake clutch components have consistent optimum performance and an extended life.

Westlake clutch kits and components, certified top-quality

Every Westlake clutch component is individually inspected and tested against set performance specifications before leaving the factory. Tests include fitment, operational capability, wear simulation, stress and fatigue testing using the latest sophisticated testing and inspection facilities. As part of our “Life Test”, clutch kits and component parts are tested using over 500,000 actuations. This ensures that all Westlake clutch components have consistent optimum performance and an extended life.

Westlake clutch kits and components, certified top-quality

- OE standards of quality and performance

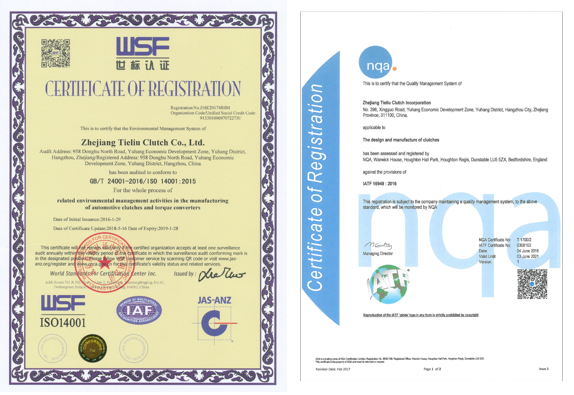

- ISO9001, ISO 14001, OHSAS 18001 and CNAS certification assurance

- Highly sophisticated total quality management system

- Dedicated production line and QC staff for export orders

- Higher standard of QC process for European orders

- Low yearly quality claim rate < 0.5